The use of foam in packaging has come a long way since its inception. Initially developed as a lightweight alternative to traditional packaging materials, foam has evolved into a sophisticated solution for a wide range of industrial applications.

Early foam packaging relied primarily on expanded polystyrene (EPS). While effective, EPS had limitations in terms of customization and environmental impact. As technology advanced, new types of foam were developed, offering improved performance and versatility.

Today, the foam packaging industry benefits from cutting-edge manufacturing processes that allow for precise control over foam properties such as density, compression strength, and shock absorption.

For example, before automated machines, contour cutting was performed by hand using patterns of paper, cardboard, wood, etc. hand drawn onto the foam and then cut using vertical bandsaws.

Today, companies such as Sterling Manufacturing use automated machines that allow intricate shapes to be cut out of large blocks or sheets of foam from CAD-CAM drawings, resulting in maximum yields from the raw material and lowering the cost per individual piece.

This technological progress has enabled the creation of custom foam solutions (including length, width, and height) tailored to specific product requirements and industry standards.

Custom Foam Solutions: Sterling Manufacturing’s Approach

Understanding Your Needs:

- Collaborative consultation process.

- Close work with clients to determine individual requirements.

- Expertise in various industries and applications.

Foam Design and Selection:

- Assistance in finding the perfect foam for specific applications.

- Utilization of extensive knowledge in foam properties and performance.

- Consideration of factors such as protection level, cost-effectiveness, and sustainability.

Advanced Foam Fabrication:

- Processing from raw bulk material to intricate CAD-drawn requirements

- Capability to handle orders from single prototypes to 1,000,000 pieces

- Wide range of fabrication services, including:

- Contour cutting

- Die-cutting

- Dimensional cutting

- Laminating and bonding

- Gluing

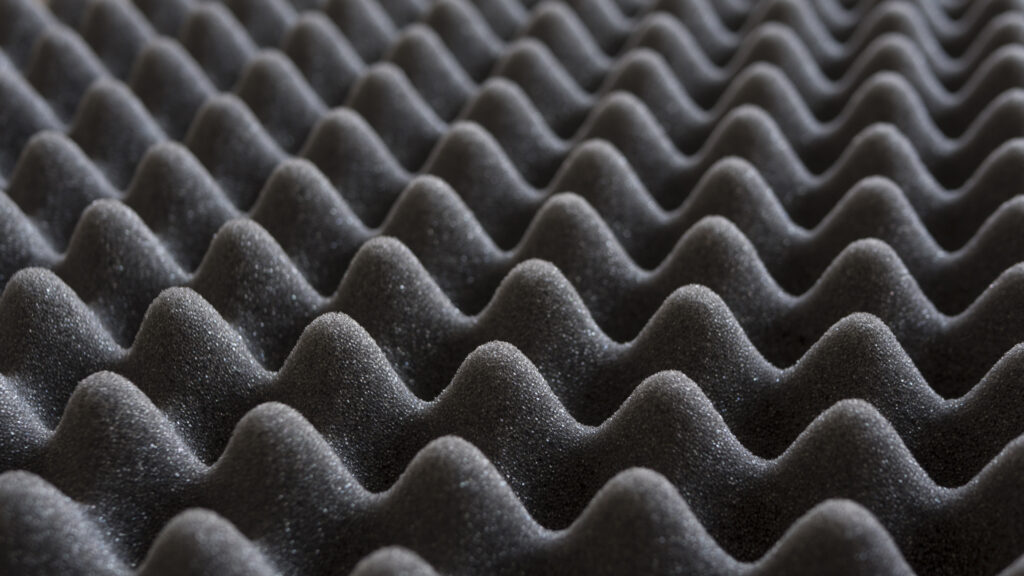

- Convoluting

Cutting-Edge Technology:

- Large warehouse equipped with both manual and automated capabilities.

- Advanced machinery for precise and efficient foam processing.

- Continuous investment in the latest foam fabrication technologies.

Packaging Solutions:

- Custom-designed foam inserts and packaging.

- Expertise in creating protective solutions for various industries.

- Focus on optimizing protection while minimizing material use and costs.

Quality Assurance:

- Rigorous quality control measures throughout the production process.

- Commitment to meeting or exceeding industry standards.

- Continuous improvement of manufacturing processes.

Efficient Delivery and Logistics:

- Meeting or exceeding client deadlines.

- Logistic support for smooth order fulfillment.

- Flexible production capabilities to accommodate varying order sizes.

Cost-Effective Solutions:

- Leveraging expertise in fabrication techniques to lower costs.

- Balancing quality, price, and service to provide optimal value.

- Scalable solutions for both small and large volume orders.

Dedicated Workforce:

- Large employee base with extensive foam manufacturing experience.

- Skilled technicians and engineers for complex foam fabrication projects.

- Committed customer support team for responsive service.

Future Trends in Industrial Foam Packaging

As the packaging industry continues to evolve, several trends are shaping the future of foam packaging:

Innovations in Foam Materials:

-

-

- Development of bio-based and biodegradable foams.

- Advanced composite foams with enhanced properties.

- Smart foams with self-healing or temperature-responsive characteristics.

-

Sustainability and Eco-Friendly Options:

-

-

- Increased use of recycled and recyclable foam materials.

- Implementation of closed-loop recycling programs for foam packaging.

- Adoption of foam alternatives made from renewable resources.

-

Integration with Smart Packaging Technologies:

-

-

- Incorporation of RFID tags and sensors into foam packaging.

- Development of foam packaging with built-in temperature and shock indicators.

- Use of augmented reality for improved packaging design and user instructions.

-

Discover the Future of Foam in Industrial Packaging with Sterling Manufacturing

Explore the incredible advancements in foam technology and see how Sterling Manufacturing leads the way in providing custom, cost-effective, and eco-friendly foam packaging solutions. From cutting-edge fabrication techniques to sustainable materials, we’re dedicated to meeting your unique packaging needs.

Ready to revolutionize your packaging? Contact us today for a consultation and discover how our expertise can enhance your products’ protection and efficiency.