When it comes to industrial packaging, foam checks all the right boxes as it’s lightweight, versatile, and cost-effective while offering superior protection.

“In the evolving world of industrial logistics, the importance of reliable packaging cannot be overstated. Among the various materials used in industrial packaging, foam stands out as a versatile and indispensable component,” says Morty Chambers, owner of Performance Packaging, which often relies on foam packaging in their customized solutions. “From protecting delicate electronics to cushioning heavy machinery, foam plays a pivotal role in ensuring products reach their destination safely and efficiently.”

Performance Packaging utilizes foam for its clients from Sterling Manufacturing, which has been at the forefront of the foam packaging industry since 1968, supplying high-quality Polyurethane, Polyethylene, and Polyurethane foam products to meet the diverse needs of various industries.

From the medical and pharmaceutical industry to the automotive industry to military and defense, foam packaging is used to protect all types of products, including sensitive equipment from impact and vibration as it makes its way through the supply chain.

Let’s explore the crucial role foam plays in industrial packaging and how Sterling Manufacturing continues to shape the industry.

Types of Foam Used in Industrial Packaging

Sterling Manufacturing specializes in three primary types of foam used in industrial packaging:

- Primarily Ether and Ester, an open cell foam available in various densities and colors for unique applications.

- Highly versatile and customizable.

- Excellent shock absorption properties.

- Ideal for fragile and high-value items.

- Also available in specialty foams like anti-static and anti-abrasive.

- Industries include furniture, bedding, automotive, electronics, acoustic, and oil & gas.

- Workhorse material available in extruded and laminated.

- Durable and water-resistant.

- Good chemical resistance.

- Suitable for repeated use and long-term storage.

- Superior non-abrasive properties and approved for Class A finish protection.

- Foam-cushion packaging sets for electronic items (computers, circuit boards, printers, monitors, and hard drives), glassware, dishes and other delicate items, and cylindrical products such as downhole tools in the pipeline industry.

Expanded Polystyrene (EPS) Foam:

- Lightweight and cost-effective.

- Excellent thermal insulation properties.

- Widely used in disposable packaging.

- Used for packaging dunnage, floatation, and insulation.

- Geofoam EPS foams ideal for building construction and architectural applications.

| Property | PU Foam | PE Foam | EPS Foam |

| Material Type | Polyurethane | Polyethylene | Polystyrene |

| Density Range | 15 kg/m³ to 100 kg/m³ | 25 kg/m³ to 300 kg/m³ | 10 kg/m³ to 40 kg/m³ |

| Cell Structure | Open or closed cell | Mostly closed cell | Closed cell |

| Rigid or Flexible | Can be flexible or rigid | Mostly flexible, can be semi-rigid | Rigid |

| Compression Strength | Good | Moderate to good | High |

| Water Absorption | High | Low | Very low |

| Thermal Conductivity | Low to moderate | Low to moderate | Low |

| Chemical Resistance | Resistant to many chemicals | Resistant to chemicals | Susceptible to some solvents |

| Flammability | Varies (can be made flame retardant) | Generally flammable | Flammable (unless treated) |

| Applications | Furniture, insulation, packaging | Packaging, insulation, flotation | Packaging, insulation, construction |

| Environmental Impact | Recyclable, some can be biodegradable | Recyclable | Recyclable, potentially reusable |

Each type of foam has its unique properties and applications, allowing packaging engineers to select the most appropriate material for specific products and shipping conditions.

Key Benefits of Foam in Industrial Packaging

Let’s review the key benefits of choosing foam for your industrial packaging needs:

Superior Protection Against Shock and Vibration:

- Foam’s cellular structure provides excellent cushioning, absorbing impacts and vibrations that could otherwise damage sensitive equipment or fragile products. This property is particularly crucial in industries such as electronics and medical devices, where even minor damage can render a product unusable.

Customizability and Versatility:

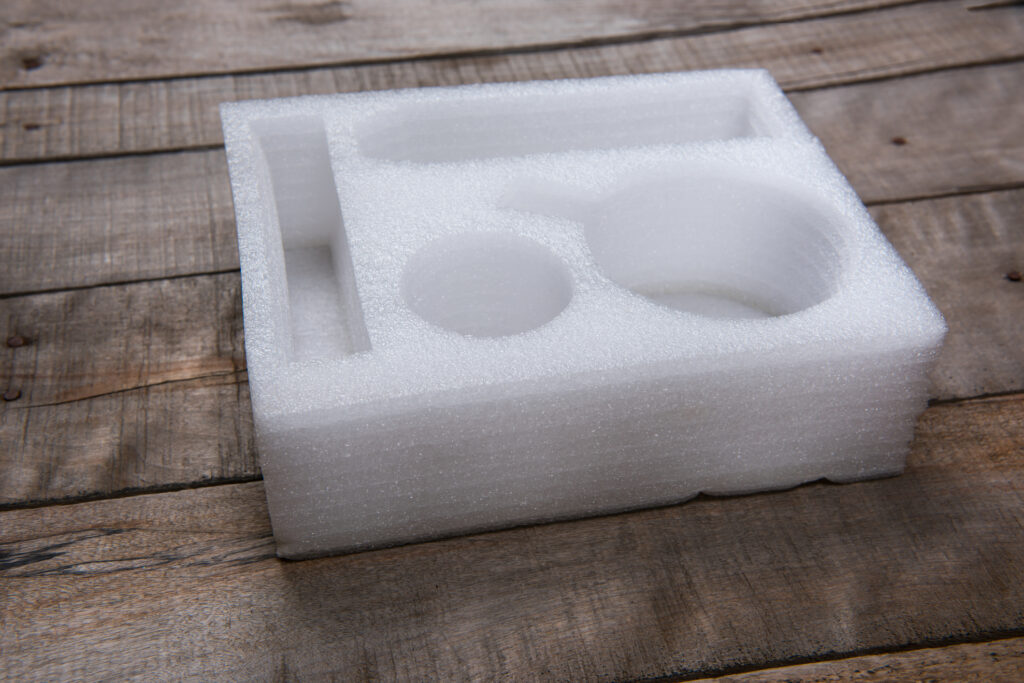

- One of foam’s greatest strengths is its ability to be molded and cut into virtually any shape. This allows for the creation of custom packaging solutions that perfectly fit and protect specific products. Sterling Manufacturing’s expertise in custom foam fabrication ensures that each packaging solution is optimized for its intended use.

Weight Reduction and Cost-Effectiveness:

- Compared to traditional packaging materials, foam is significantly lighter, which can lead to substantial savings in shipping costs. Additionally, the durability of foam packaging often allows for reuse, further enhancing its cost-effectiveness over time.

Sustainability Considerations:

- While foam has historically been associated with environmental concerns, advancements in materials and manufacturing processes have led to more sustainable options. Sterling Manufacturing is committed to exploring and implementing eco-friendly foam solutions to meet the growing demand for sustainable packaging.

Industry-Specific Applications of Foam Packaging

A diverse range of industries, each with its unique packaging requirements, take advantage of foam packaging.

Here’s how foam packaging plays a crucial role in various sectors:

Furniture & Bedding:

- Custom-cut foam inserts protect delicate furniture components during shipping

- Foam padding prevents scratches and dents on finished surfaces

- Mattress foam packaging ensures hygienic delivery and easy unpacking

Military:

- High-density foam protects sensitive equipment in rugged environments

- Custom foam cases for weapons and communication devices

- Shock-absorbing foam inserts for ammunition and explosives packaging

Oil & Gas:

-

- Foam packaging for fragile measuring instruments and sensors

- Custom foam inserts for valves, fittings, and small parts

- Thermal insulation foam for temperature-sensitive components

Engineering & Construction:

- Protective foam packaging for precision tools and instruments

- Custom foam inserts for survey equipment and laser levels

- Impact-resistant foam cases for power tools and accessories

Electronics:

- Anti-static foam for sensitive electronic components

- Custom-molded foam inserts for consumer electronics

- Shock-absorbing foam packaging for servers and networking equipment

Medical & Pharmaceutical:

- Sterile foam packaging for medical devices and implants

- Custom foam inserts for diagnostic equipment and lab instruments

- Temperature-controlled foam packaging for pharmaceutical products

Automotive:

- Foam packaging for delicate car parts such as mirrors and lights

- Custom foam inserts for automotive electronics and sensors

- Reusable foam packaging for just-in-time manufacturing processes

With over 50 years of experience in processing Polyurethane, Polystyrene, and Polyethylene foam, Sterling Manufacturing offers a comprehensive approach to meet all your foam packaging needs. Their expertise and state-of-the-art facilities ensure high-quality solutions tailored to your specific requirements.

Sterling Manufacturing’s goal is not only to meet but to exceed client expectations in terms of quality, price, and service.

Foam plays an indispensable role in industrial packaging, offering unparalleled protection, customization, and cost-effectiveness across a wide range of industries. As packaging requirements become increasingly complex, the importance of innovative foam solutions continues to grow.

Sterling Manufacturing, with its long-standing expertise and commitment to quality, is well-positioned to meet the evolving demands of the industrial packaging sector. By combining cutting-edge foam technologies with customized solutions and excellent service, Sterling continues to be a trusted partner for businesses seeking top-tier industrial foam packaging.

Sterling Manufacturing has the expertise and capabilities to provide the foam packaging solutions you need. Contact us today to discover how our custom foam fabrication services can enhance your product protection and streamline your packaging processes.