Any retailer wants to make sure their packages arrive on time and intact. The best way to make sure they arrive safely is to provide durable packaging. When it comes to providing protection for products throughout the many stages of storage, and shipment customers often wonder if shrink wrap or stretch wrap is the better option.

While there are several differences between the two, they commonly get mixed up. Shrink wrap is an allusive term applied to multiple different things, and it often gets misused. It is most commonly confused with stretch wrap.

What is Shrink Wrap?

Shrink wrap is a loosely fitting transparent plastic film that shrinks to a package when heat is applied. It does not have the cling-type effect that saran wrap has. It is often used to wrap a single product but, in some cases, can wrap multiple products together. Shrink-wrap protects containers during shipping and transit if it is applied correctly. It may also protect the product from hazardous weather and moisture.

Unlike stretch-wrap film, which is wrapped around a full pallet of products multiple times, shrink wrap is cut around the specific product using a shrink wrap bar or sometimes a heat sealer.

There are few different kinds of shrink wrap, including PVC shrink wrap, which is mainly used in packaging items like gooks, dog toys, gift bags, etc. It is quite flexible and strong and is one of the thicker types of shrink wrap.

Polyolefin Shrink wrap is another kind that makes an excellent choice for displaying items that need to be together. It is also FDA-approved for direct food contact.

Pizza shrink film is another food-safe film that is often what frozen pizzas are wrapped in. it is just light enough for fast-shrinking yet sturdy enough to contain a pizza. It also is easy to tear off, which makes it the perfect wrap for food products.

Barrier shrink bags are more of a vacuum bag for food packaging and are often used for sausages and cheeses.

What are the Benefits of Shrink Wrap?

- Protection is one of the most significant benefits to shrink wrap. It is excellent for providing protection from weather, dust, dirt, and moisture.

- Surface damage is not an issue when using shrink wrap. When the wrap is applied correctly, the likelihood of damage during shipping decreases drastically.

- Breathability is an added benefit to today’s shrink wrap. It can be ventilated, which significantly reduces the likelihood of moisture damage.

What is Stretch Wrap?

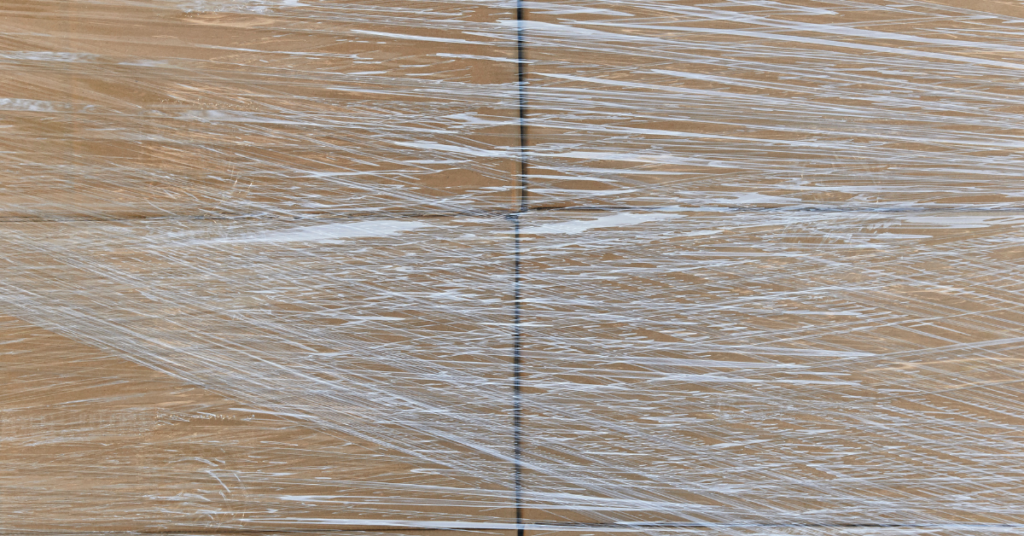

Stretch wrap, also sometimes known as stretch film, is a clear plastic film that appears similar in appearance to saran wrap. It is often used to bundle or wrap items together, offering an added layer of protection during storage or shipment.

Stretch wrap has a tendency to stick together when it is wrapped over itself, much like saran wrap. It can be applied in a couple of different ways. The first method involves manually wrapping the material around the product. The other method involves machines that wrap the product.

These stretch wrap machines are designed to quickly and efficiently apply the wrap to the products, and heat is not necessary to apply. When applied with a machine, Stretch wrap can stretch up to 150% to 300% more. After its application, it undergoes film testing, which determines which characteristic the film requires in order to fulfill its purpose effectively. Tests can be run at this point to determine potential hazards commonly found during transport.

What are the Benefits of Stretch Wrap?

- Price is one of the major benefits of stretch wrap. It is significantly less expensive than other types of materials to wrap pallets. The equipment is also far less expensive than comparable machines used for wrapping.

- Protection is another benefit. Stretch wrap has been used for decades to secure and protect products from moisture and dust. In some cases, depending on the film, it can also offer protection against UV rays.

- The versatility of stretch wrap is another major benefit. It can be suitable for virtually any and every application. It is even applicable for various surfaces.

Stretch Wrap vs Shrink Wrap

Material

One of the most significant differences between stretch wrap and shrink wrap is the material the plastics are made from. Stretch wrap is most commonly made from polyethylene resin, while shrink wrap is greeted from polyolefin film.

Uses

Stretch wrap is mainly used in warehouses and distribution centers to wrap pallets of products for storage and shipment. Stretch wrap is offered for a variety of specialty custom fils such as colored stretch fil, UV stretch wrap, and pre-stretched film.

Shrink wrap, on the other hand, is most commonly used to protect a single product from weathering or dust. It is also used quite often to wrap smaller products together tightly. It is more commonly used for protecting items like boats, outdoor furniture, and food items for vacuum sealing purposes.

Based on the many different types of wrap, whether it is shrink wrap or stretch wrap, the basic characteristics in common include the film wrapping products.

Here at Sterling, we can use our automatic or semi-automatic wrapping machinery, and we are able to shrink wrap a variety of products and packages, up to 21″ wide, 33″ long, and 10″ tall.

This type of packaging is ideal for bundling/unitizing packages or products together, keeping packages or products clean, providing tamper evidence, and deterring theft. We only use films with the highest clarity for your retail products to give your product a clean, crisp look.

Thank you for letting us know that a shrink wrap is used to prevent surface damage by protecting against weather, dust, dirt, or moisture. My brother manages a construction firm, and it seems like they need a new supply of shrink wraps to use for their upcoming projects soon. I hope they are able to find a trusted industrial supplier to contact for the shrink wraps they need for the projects.