Foam is ubiquitous in various products, from mattresses to car seats. It is known for its versatility and ability to conform to any shape or size. Foam fabrication companies specialize in creating custom foam products that meet the unique needs of their clients. This article will discuss how foam specialties can help meet your custom needs.

Understanding Foam Fabrication

Foam fabrication involves using specialized machines and techniques to create custom foam products. These products can be used in a variety of industries, including automotive, medical, and aerospace. Foam specialties companies have the expertise and experience to create foam products that meet the specific needs of their clients. They can work with a range of foam materials, including polyurethane, polystyrene, and polyethylene.

The Benefits of Custom Foam Products

- Perfect Fit

Custom foam products are designed to fit specific dimensions or shapes, making them ideal for use in products that require a snug fit, such as cushioning for medical equipment or insulation for electronic devices.

- Optimal Performance

These products can be formulated to meet specific weight, compression, and performance requirements. This is important in industries such as aerospace and automotive, where precision and performance are critical factors in product design.

- Aesthetically Pleasing

Custom foam products can be designed to meet specific aesthetic requirements. This is important in industries such as furniture and interior design, where the product’s appearance is as important as its function. Custom foam products can be created in a range of colors and textures to match the product’s design and enhance its visual appeal.

The Foam Fabrication Process

- Design and Specification

The foam fabrication process begins with the client providing specifications for the product, including dimensions, material, and performance requirements. - 3D Modeling and Prototyping

The foam fabrication company uses specialized software to create a 3D product model, allowing the client to visualize the product before it is manufactured. Once the design is approved, a prototype is created to ensure the product meets the client’s specifications. - Fabrication and Inspection

Once the prototype is approved, the foam fabrication company uses specialized machinery to create the final product. This can involve cutting, molding, or shaping the foam to the required dimensions. The final product is then inspected to ensure that it meets the client’s specifications, including weight, compression, and appearance.

The Importance of Working With a Foam Specialties Company

Foam fabrication requires specialized machinery and expertise. Working with a foam specialties company with the experience and knowledge to create custom foam products that meet your specific needs is important. Foam specialties companies have the resources to create products that meet the highest quality standards. They also have the expertise to provide advice on the best foam material and design for your product.

Foam specialty companies also offer a range of services beyond foam fabrication. They can provide advice on product design, material selection, and performance requirements. This ensures that your product is functional and meets your aesthetic requirements.

Foam fabrication is a complex process that requires specialized machinery and expertise. Foam specialties companies have the resources and knowledge to create custom foam products that meet your needs.

Custom foam products offer a range of benefits over off-the-shelf products, including the ability to meet specific dimensions, performance, and aesthetic requirements. When choosing a foam specialties company, looking for a company with the experience and expertise to deliver high-quality products that meet your specific needs is important.

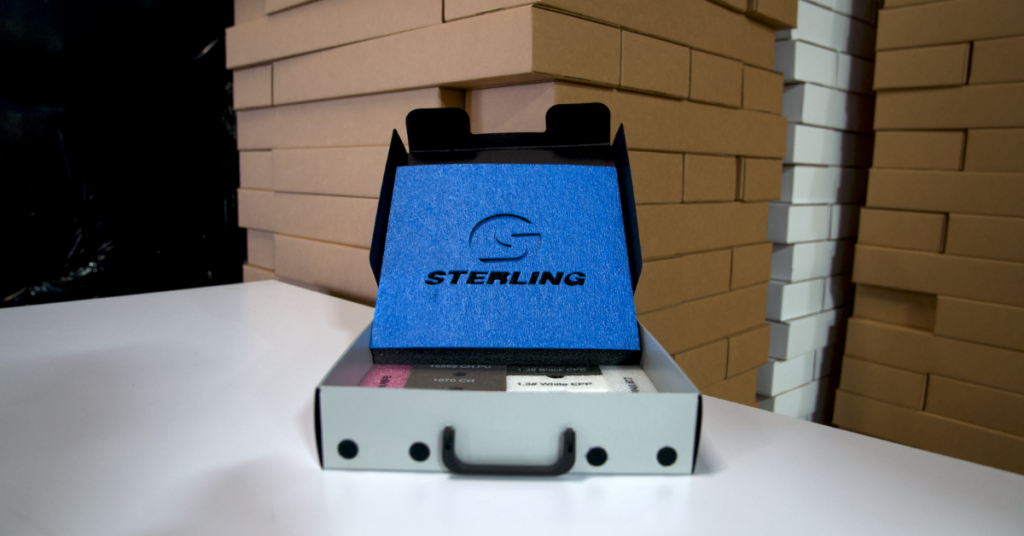

Looking for high-quality foam fabrication products? Look no further than Sterling Manufacturing & Distributing! As experienced foam fabricators, we can create custom foam products to meet your specific needs. Request a sample box today!