Polymers are ubiquitous materials that have revolutionized the world of manufacturing and packaging. They are used in various industries, including construction, automotive, medical, and food packaging.

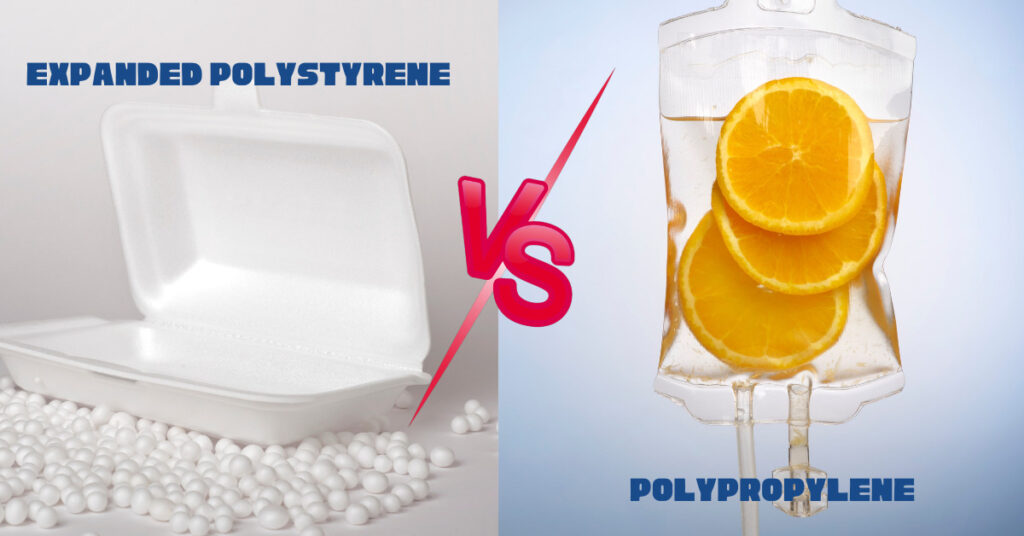

Two common types of polymers are expanded polystyrene (EPS) and polypropylene (PP). Each of the materials, as mentioned earlier, possesses distinct characteristics that render them appropriate for diverse uses.

Read on to learn about EPS and EPP and their typical applications.

Expanded Polystyrene (EPS)

EPS is a lightweight, rigid, closed-cell foam plastic with excellent insulation properties. The material is derived from polystyrene beads that undergo expansion through steam and subsequent molding into diverse configurations and dimensions.

It is a widely utilized material within the construction sector due to its insulating properties, packaging capabilities, and diverse applications.

Here are some of the standard applications of EPS:

1. Insulation

EPS is an excellent thermal insulator due to its low thermal conductivity. It is used in construction as insulation for walls, roofs, and floors. EPS insulation panels are lightweight and easy to install, making them a popular choice for energy-efficient buildings.

2. Packaging

Expanded polystyrene (EPS) is frequently used in the packaging sector due to its exceptional cushioning characteristics. It packages fragile items such as electronics, appliances, and glassware. EPS packaging is lightweight, inexpensive, and recyclable, making it eco-friendly.

3. Molded Products

EPS can be molded into various shapes and sizes, making it suitable for multiple applications. Disposable cups, plates, and cutlery are manufactured using this material. EPS is also used in the automotive industry to make parts such as seat cushions, headrests, and armrests.

Polypropylene (PP)

Polypropylene (PP) is a commonly utilized material in manufacturing and packaging. The material in question exhibits excellent chemical and thermal resilience and is highly adaptable in its applications.

Polypropylene (PP) has widespread usage in various applications.:

1. Packaging

(PP) It is a preferred material in the packaging sector due to its exceptional robustness and ability to withstand moisture and chemical exposure. It is used to make various types of packaging, including food containers, bottles, and bags.

2. Automotive Industry

(PP) It is a popular choice in the automotive sector due to its exceptional durability and resistance to high temperatures and chemical substances. It makes parts such as bumpers, dashboards, and door trims. PP parts are lightweight and have excellent impact resistance, making them suitable for high-stress areas.

3. Medical Industry

PP is widely used in the medical industry due to its excellent chemical resistance and low toxicity. It makes various medical devices such as syringes, catheters, and IV bags. PP medical devices are safe, sterile, and disposable, making them suitable for single-use applications.

Advantages Of Using Expanded Polystyrene & Polypropylene

EPS and PP offer unique advantages and benefits, making them popular application choices. Both materials are lightweight, durable, and versatile, making them ideal for packaging, construction, and manufacturing.

They are also recyclable, making them environmentally friendly choices. EPS and PP are excellent choices for those seeking reliable, cost-effective, and sustainable materials for their projects.

Conclusion

Polymers have revolutionized the world of manufacturing and packaging, and EPS and PP are among the most commonly used polymers. They have unique properties that make them suitable for different applications. Their use has contributed to the development of energy-efficient buildings, eco-friendly packaging, and safe medical devices.

Are you looking for high-quality, durable EPS expanded polystyrene? Look no further than Sterling Manufacturing and Distributing! Our EPS products are made with top-notch materials and technology to ensure exceptional performance and longevity. Whether you need EPS for packaging, insulation, or construction, we’ve got you covered. So why wait? Contact us to get started on your next EPS project and experience the Sterling difference!